Laminated glass vs tempered glass, do you know the difference?

Laminated glass, safety, tempered, low emissivity… how difficult it is sometimes to make a decision! And if you have to choose your future windows or just thinking about changing them, you will have to opt for one of them.

The glass can be presented in many ways, its characteristics are a consequence of the process of elaboration of each type. The flat glass produced by means of the flotation process is often subsequently treated to give you certain specific qualities or characteristics. In this way, the industry can meet the different requirements and needs of construction, the automotive industry or solar energy, let's see some types:

• Annealed basic glass: cooked glass is the basic product of flat glass, it is the first result of the flotation process. It is the common glass that tends to break into large, jagged pieces. It is often used in single or double glazing windows, it is also the starting material which becomes more advanced products through processes such as lamination, hardening, coating, etc.

• The armed glass has a steel mesh inside, which does not make them stronger, but in case of breakage it acts as temporary support. Aesthetically speaking, they lose transparency.

• Thermo-hardened or semihardened glass is a glass to which a heat-based treatment has been applied in order to improve its performance. Better thermal and mechanical resistance is achieved.

Glass not only makes our favorite places more comfortable, luminous and attractive, but also can provide security to all people who make life in such enclosures. A safety glass will protect people from injury in the event of accidents and their property and property against theft, vandalism and breakages. The most important property of the safety glass is that, in case of breakage, this does not present potential to cause injuries of consideration to the people. In addition to this, because of the treatments they undergo, they are extremely difficult to be pierced by the impact of people or objects, thus offering greater protection.

Tempered Glass

Tempered Glass is a safety glass that has been processed with heat or chemical treatments to increase its resistance to normal glass. Its inner surface is in tension, to the point that when the glass breaks it crumbles into small pieces instead of jagged fragments so that it cannot cause injury.

Main features of tempered glass

Weight and impact resistance. Tempered Glass presents a notable increase in mechanical strength. The process used for its manufacture causes a stronger bond between the crystal molecules, this means that the glass can be used in applications that require a stronger and more transparent surface. Faced with an impact, this glass is tearing in very small pieces and unable to hurt anyone.

Soundproofing. The thickness of the glass is a determining factor in the acoustic insulation of the windows or the enclosures covered by glass. A simple glass or tempered glass of common thickness would attenuate approximately 20 decibels of outside noise, very little to be considered an effective barrier against noise pollution.

Resistance to manufacturing manipulations. Tempered Glass, thanks to its moderate thickness, flexibility and high mechanical strength, is suitable for drilling and handling more easily; This makes it ideal for use in works where it should be mixed with hardware, complex notches or even to make pieces with serigraphy.

Light filtration and UV rays. Compared to laminated glass, tempering is usually very translucent and lacks sun protection. However, it is extremely useful for double glazed laminated glass windows, as it reinforces the piece and makes it more resistant to direct heat from the sun, the inclement cold of a winter or the possible

The Color, originates from the elements that are added at the moment of its merging. Thus for example a bluish-red color will be achieved by the use of cobalt oxide; A yellow color will be obtained by using ferric oxide and a bluish coloration will be achieved by the use of ferrous oxide.

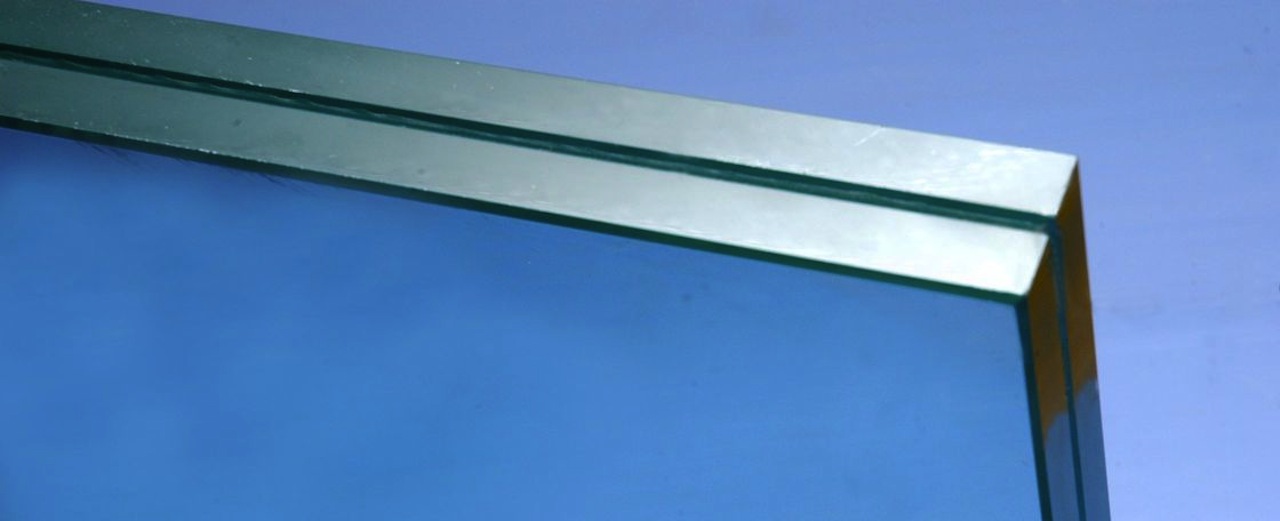

Laminated Glass

The laminated glass consists of the joining of several sheets of glass (hence its name) by means of an intermediate film made with PVB (prevents the glass from breaking easily), EVA and resins activated by ultraviolet light. The blades can receive an acoustic and solar control treatment. With these sheets the glass becomes more resistant to breakages, as the pieces are attached to lasa these. Unlike tempered glass, not all laminated glass is safety.

Main features of laminated glass

Resistance to penetration, due to burital blade. This is undoubtedly its most notable feature, hence recommending its installation for use with special requirements for security and protection of people and property. Fragmentation, a plus, as mentioned, because, in case of breakage, the fragments are adhered to the glue.

Sound insulation: We've also discussed it before. This type of glass improves the acoustic attenuation of the house thanks to its composition, achieving a greater comfort for your home and definitively banishing the noise.

Shock-resistance, thanks to the elasticity of the PVB glue, thus achieving greater protection against impacts. The justification is that before a blow on the laminated glass, the PVB absorbs the energy of the impact and thanks to its elasticity maintains the adherence to the crystal.

Transparency and durability. The composition that includes the PVB film does not alter the qualities of the glass, such as transparency or durability (which in this case, in addition, is enhanced).

Light filtration and UV rays. The laminated glass is ideal for windows and glazed ceilings, as well as its strength and thickness, the sheets of PVB make it also offers great protection against UV rays, absorbing 99.5% of them. This property prevents discoloration and deterioration of interior goods by contact with sunlight.

Color: There are many possibilities to be able to put the glass of color, because the sheets can be transparent, translucent, opaque… and also with colors.

Applications of laminated glass and tempered glass

Shower screens. The most frequent use is tempered glass, the greater thickness the better resistance, but it will condition the hardware by the tolerable thickness, now if what we need is a fixed that does not carry notches, nor drills, nor any additional interior manufacture in the glass, You can always use a laminated glass.

Window glass: Laminated glass is normally used, although they can be combined with other tempers to increase safety and antiaggression resistance.

We also recommend the use of tempered glass in applications where the glass may be subject to sudden changes in temperature (stress or thermal shock). For example, if you have a showcase or window with shade as a result of projections or extensions of the building, the shaded area will be colder, so you can generate tensions that cause thermal break (for different dilation coefficients) . In these cases it is recommended to carry out a thermal stress analysis to determine the need to temper the glass.

Trades and public spaces: usually a combination of both, the covers of tempered for all those glasses that have notches, drills, etc… And that in some way are mechanical elements as well as the enclosed glass to preserve thicknesses and aesthetics of the glass, and laminated in the rest of spaces.

Interior and exterior Handrails: If the glasses are received on metal support and do not carry any interior manufacture, it would be worth with laminated glass. However, if the glasses are buttoned, hooked with fittings inside or similar it would be necessary to temper the glass. If there is a risk of falling at different levels, we will always use laminated glass, and if necessary, hardened laminates.

Building windows: If we are going to use double glazing compositions, the outer face should always use a safety glass (tempered or laminated). In addition, it is highly recommended to use a safety glass inside.

Military and personal safety uses antiaggressions: These will be all laminated glass, but with a peculiarity, depending on the type of aggression to which we are exposed, the thicknesses and the configurations of resistance are changing, being able to use Special materials for lamination and special treatments that increase resistance.

Steps and tread surfaces: it is very important to calculate the thickness of the glass to be used, and it is usually advisable that the surface that receives the contact, will withstand better erosion, impacts, tractions and Flexiones. In the same way as in other sections, depending on the use, the transit and the situation, it is advisable to make a compact block by laminating several tempered or unmonoliticosed glass. Always, the transit surface is essential to give some type of anti-skid treatment, since the glass in contact with the water, removes in a important way the adhesion.

While it is true that these safety glasses have notable differences among themselves, it is important to note that both are extremely strong and have many properties in common. One of the things to consider is the fact that you can manufacture a tempered-laminated glass to take advantage of the qualities of both crystals; However, your choice will always depend on the purpose you are going to give to the piece.

If you are still in doubt about choosing the ideal safety glass for your project, we at Acertus can help you. Remember that you can also rate your work by filling out the quotation form. Our team will be happy to assist you.